Since March 2018, more than 100 vessels were reported having operational failure due to seemingly on-spec residual fuel contamination. This incident has packed a hard punch in the industry and in light of these issues, the industry especially shipowners have brought up their concern on the quality of new fuel blend supplied to meet to IMO 2020 sulfur limits. Many have foreseen the similar contamination case are going to happened more frequent because of the increased number of experimental new blend fuel recipes and the surge of opportunistic blender to provide compliant fuel.

The new fuel blend caters for IMO 2020 sulfur requirement has received massive concern and argument in term of fuel stability and compatibility. This is because there is no standardization and clear guideline on blending and fuel oil blends expected to vary widely across the regions. The supplier will only make sure fuels or cutter stocks used in fuel blending are in accordance with ISO 8217 specification and IMO requirement, however, the compatibility of fuel is not guaranteed by supplier and the responsibility falls on shipowner. Shipowners is advisable to look at the stability of fuel and the risk of incompatibility when using consecutive fuels from different ports and regions.

Incompatible and unstable fuel undergoes abnormal chemical changes and forms viscous thick sludges in storage tank which lead to clogged filter, separator and pipes line. In worst scenario it will cause permanent damage of engine pistons and stop the main and auxiliary engines that endanger the ship and its crew. The shipping company will suffer from service disruption, longer transit time and serious cut of their revenue.

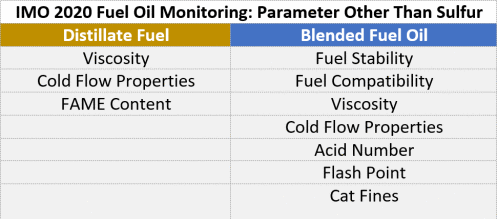

Therefore, while meeting the sulfur requirement of IMO 2020, shipowners were asked to monitor other marine fuel parameters stated in ISO 8217:2017 as frequent as possible to ensure fuel safety and stability. The essential parameters including density, viscosity, flash point and cold flow properties (cloud, pour and filter plugging point). In the latest revised ISO 8217 specifies the requirements for a -6 °C pour point (PP) in winter and 0°C in summer. Additionally, ISO 8217 now also calls for cloud point (CP) and cold filter plugging point (CFPP) reporting to ensure operability for all ships in all climates. Another essential aspect that required attention is the fuel compatibility testing, ASTM D4740 was used by the marine industry for fuel compatibility testing and ASTM D7845 by GCMS was used for fuel contamination monitoring. However, both methods have their limitation. In the recent CIMAC Guideline for ISO 8217:2017 suggested that fuels with the same viscosity grade and similar densities are likely to be compatible but the composition of the actual fuel play an important role as well.

Our main concern is the way refiners compose blends will vary compared to the uniformity of fuel specification we have right now. We will no longer have a consistent product throughout the world but potentially a very different product from one region or refinery to the next.”

Lars Robert Pedersen, deputy secretary-general at BIMCO.